Cleaning

In order to prolong grip life and promote safety, EKC Systems Ltd recommend all prestressing grips are cleaned regularly. This should be an integral part of any factories safe system of work. The grips should be cleaned then lubricated before any stressing operation takes place.

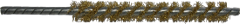

Cleaning Brushes |

|

|

To aid cleaning EKC supply a range of wedge and barrel cleaning brushes. These feature tough, durable bristles that can be fitted into any hand held or fixed power drill chuck. The wedge brushes are available in two sizes for either wire or strand. They clean into each wedge thread, removing the rust and grime, which has accumulated during the prestressing operation. The barrel brushes are specially tapered to enable thorough cleaning of the barrels internal taper bore. They can be easily fitted into a hand held drill for ease of operation. |

Ultrasonic Cleaning |

|

|

Special Ultrasonic cleaning tanks are available in a variety of sizes to suit the customers individual requirements. These automatic machines clean grips quickly and efficiently to improve both wedge life and safety. For normal duty we have the 2.5 to 28 litre Standard Bench Top cleaning units but for the larger user we are also able to provide an industrial range in 5 to 95 litre capacity. Other sizes are available to special order. |

|

|

|