Lifting Equipment

EKC Systems Ltd offer a wide variety of lifting equipment to suit our customers needs. All lifting equipment sold by EKC Systems Ltd is in accordance with CE regulations.

All EKC lifting systems are recommended personally for use by main suppliers of concrete stairs, beams & flooring, making us an efficient & reliable supplier. Shackles & ring clutches can be purchased for regular usage or hired for contract occasional purposes.

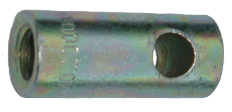

Lifting Insert |

|

|

The cast-in insert provides an alternative to the lifting socket. It is made from tube that is threaded internally at one end and flattened with a cross-drilled hole at the other end to accept the reinforcing bar. They are available in both stainless steel and zinc plated steel to offer some protection against corrosion. Normally supplied without plastic sealing caps but these are available to order. Lifting insert data sheet |

Lifting Socket |

|

|

The system comprises a cast-in lifting socket, which is drilled laterally below the threaded portion in order to take a reinforcing bar that is located and tied to the main reinforcement to provide the user with a positive and secure anchorage point. They are available in both stainless steel and zinc plated steel to offer some protection against corrosion. Each socket can be supplied with two plastic inserts. The upper one (optional extra) is used to prevent ingress of dirt into the threads whilst the lower one (standard) is used to prevent ingress of concrete during the casting process. Lifting socket data sheet |

Plate End Socket |

|

|

Plate end sockets comprise a threaded socket with a flat plate welded to its base Reinforcement bars can be positioned directly on the flat steel, transmitting the tensile forces safely onto the concrete. The reinforcement plate may be welded or tied to the plate. Plate end sockets are for use in concrete panels where there is insufficient depth to allow the use of standard sockets e.g. fascia panels, floor panels' etc. All plate end sockets can be supplied with a plastic insert (optional extra) to prevent ingress of dirt into the threads during the casting process. Plate end socket data sheet |

Wavy Tail Anchor |

|

|

The Wavy Tail Socket Inserts are complete reinforced anchors for installation into precast units of all sizes e.g. Safety barriers. The unique design of the reinforcing tail safely transmits the tensile forces into the concrete, alleviating the need for additional reinforcement. All units can be supplied complete with a plastic cap (optional extra) to prevent contamination of the socket thread. Wavy tail anchor data sheet |

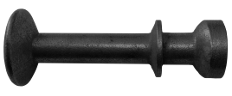

LIfting Loop |

|

|

EKC lifting loops are manufactured from wire rope held in a steel ferrule to which a standard isometric external thread is added, to mate with the steel sockets or inserts. Each lifting loop is tested to twice its working load and is certified. Steel tags on the loops indicate the safe working load and carry the loops individual serial number. All loops supplied comply with The Supply of Machinery (Safety) Regulations" 1st January 1995. Lifting loop data sheet |

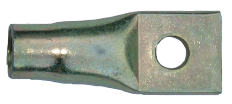

Fixing Insert |

|

|

Fixing inserts provide a simple and competitive fixing in concrete. Supplied with a flattened end cross-drilled to accept a reinforcing bar. It is essential to screw the bolt over the full thread length. The safe working loads of the fixing insert can be increased by adding formed rebar of sufficient length. Care should be taken when inserts are placed close to the edge of concrete or in groups as their loading capacity is reduced. This also applies when the insert is in a recessed position. Installation guidelines can be obtained from the EKC Engineering section. Fixing insert data sheet |

Bent Tail Fixing Insert |

|

|

Fixing inserts provide a simple and competitive fixing in concrete. Supplied with a flattened end bent through 90 degrees. The recommended safe working loads are obtained by applying a safety factor of 4.5 to the average pullout load of inserts in 22.5N/mm² concrete. These inserts are for fixing only and are not recommended for lifting or high load applications. Bent tail fixing insert data sheet |

Spherical Head Anchor |

|

|

Made of special steel with guaranteed notch impact strength and highly resistant to brittle failure. Available in a large range of sizes from 1.3 ton to 32 ton with a varied selection of lengths to suit customer applications. The recommended safe working loads are obtained by applying a safety factor of 3 to the average pullout load of spherical head anchors in 22.5N/mm² concrete. Spherical head anchor data sheet |

Spherical Double Head Anchor |

|

|

The Double Headed Anchor is specially designed for the application in combination with special rubber formers. These are often used in pits, on which the holes are firmly mounted on the formwork and remain on the formwork during the breaking away. Spherical double head anchor data sheet |

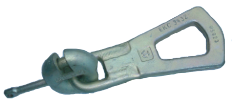

Spherical Head Lifting Shackle |

|

|

The spherical head-lifting shackle is used with the spherical head lifting pins. Even under load, movement is possible in 3 axis and if correctly fitted accidental uncoupling is impossible. These come in a range of sizes, with the size of shackle you require being determined by the size of spherical pin cast into the unit. Spherical head lifting shackle data sheet |

Spherical Head Rubber Former |

|

|

Forming device for spherical head anchor, complete with fixing plate. The former provides a void for insertion of a lifting shackle. Spherical head rubber former data sheet |

Spherical Double Head Rubber Former |

|

|

Forming device for spherical double head anchor, complete with fixing plate. The former provides a void for insertion of a lifting shackle. Spherical double head rubber former data sheet |

Spread Anchor |

|

|

A 2 dimensional lifter with the stress transfer to the concrete occuring through the reinforcement bar and the lower spread of the anchor. Spread anchor data sheet |

Erection Anchor |

|

|

The stress transfer to the concrete occurs over the reinforcement bar in the lower hole. The shoulders of this anchor prevent spalling of concrete elements when lifting from a flat position. Erection anchor data sheet |

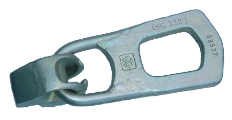

Spread Anchor Ring Clutch |

|

|

The Ring Clutch system is used with the spread anchors. Similar to the shackles even under load, movement is possible in 2 axis and if correctly fitted uncoupling is impossible. These also come in a range of sizes and again this is determined by the size of anchor that is cast into the unit. Ring clutch data sheet |

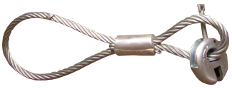

Wire Rope Ring Clutch |

|

|

The wire rope ring clutch is used in conjunction with the spread anchor system. Even under load, movement is possible and if correctly fitted uncoupling is impossible. Wire rope ring clutch data sheet |

Spread Anchor Rubber Former |

|

|

Forming device for the spread anchor lifting system, installation occurs through a fixing plate. The former provides a void for insertion of a ring clutch. Spread anchor rubber former data sheet |

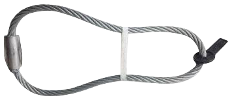

Cast In Loop |

|

|

The cast-in loop is used to lift reinforced concrete elements. The cast-in loop is situated in the concrete element at the open side of the mould. The thimble is situated in the mould. All markings must be visible after placing the concrete. Hoisting hooks of appropriate diameter can be inserted directly into the protruding cast-in loop. Care must be taken when storing the prefabricated element that the cables do not kink. The withdrawal from use of the lifting loops is to be determined in accordance with the regulations for hoisting cables of the country of use. The installation and application of lifting anchor systems must be available in plant and on site. The national safety regulations for lifting anchors and systems must be obeyed. Cast in loop data sheet |