Professional Prestressed Concrete Blades

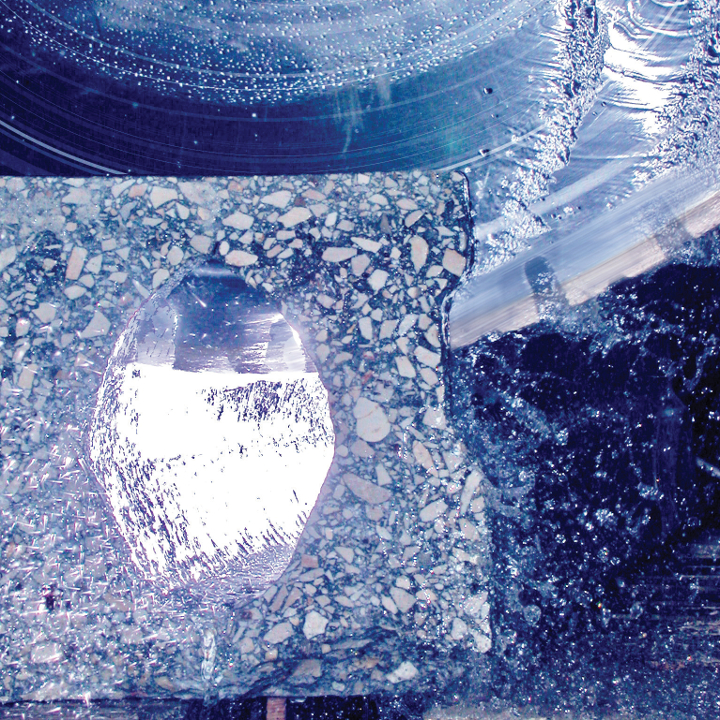

- Over 45 years of experience in the development and production of professional diamond tools

- Knowledge and skill in all types of hollow core saw machines worldwide

- Solutions and optimization according to customer needs

- 100% quality assurance (QA)

Please click here to visit their website.

Bonding system:

Toolgal possesses various types of bonding systems according to the customer’s working conditions and the concrete aggregates.

Innovation:

Toolgal GE LINE – The company has launched an innovative bonding system

The new technology permits higher output (speed, life performance) and is especially designed as an environment friendly product (no heavy metals).

Segment shapes and structure:In order to maximize the tool efficiency, Toolgal combines the bonding system with the right shape and inner structure of the segment. |

|

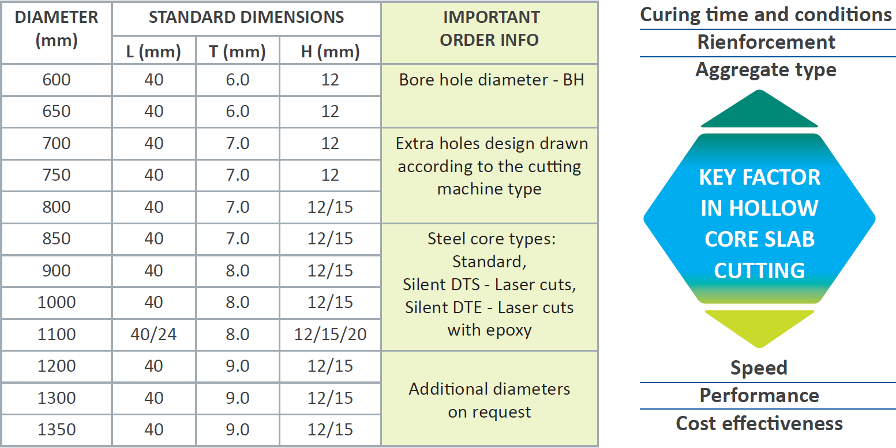

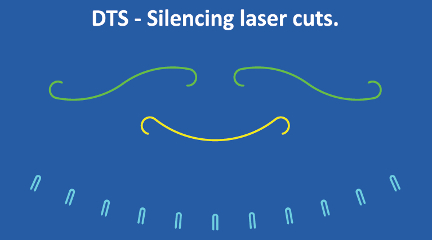

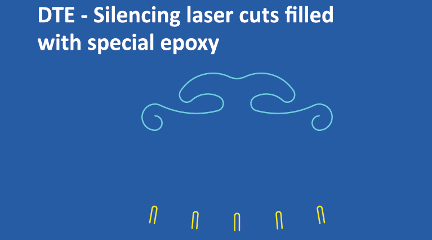

STEEL CORE TYPES: |

|

|

There are four steel core types. The main difference between them is the noise level when in use.

|

|

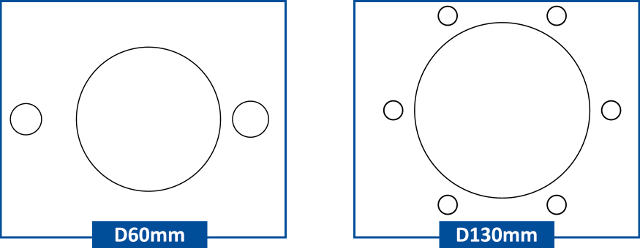

Standard bore holes:

Toolgal stock steel cores that fit most of the popular bore-hole sizes.

- 60mm + 2 extra holes

- 100mm

- 130mm + 6 extra holes

- Other bore holes in request

Cutting speed and life performance:

Cutting speed is mainly affected by slab thickness, curing stage, type of aggregates and cable reinforcement content.

The optimal speed (limestone aggregates) 200mm slab is 1.8- 2 m/Min and can drop to 0.5-0.8 m/Min in 500mm slabs.

The blade life is mainly affected by aggregate type, curing stage and machine maintenance condition.